Oil Based Metalworking Fluids for Difficult Machining Operations

Oil based metalworking fluids are used in tough operations where lubrication and extreme pressure properties are required. With the correct formulations of additives, cutting oils provide significant improvements in cutting and grinding operations by reducing friction which results in better surface finishes and longer machine tool life. They are particularly ideal for use with grinding wheels and other abrasive tools. Though oil based cutting fluids do not replace water based fluids, where cooling properties are most important, they are instead used in applications where lubrication is more important than cooling.

Grinding and cutting oils are specially designed for optimum performance in many different operations. Some of their specific advantages include:

- Long or continuous service life of fluids

- Exceptional lubricity

- Excellent rust control

- Less fluid and sump maintenance

These high performing cutting oils range from low to high viscosity. They provide ideal performance characteristics in light to heavy duty machining where lubrication power is necessary, such as gear cutting, grinding and broaching. They are also beneficial for applications where surface finish and extended tool-life are essential.

In machining operations, the metal surface of the cutting tool will always come into contact with the metal surface of the workpiece. It is at this point where the type of fluid film is critical, where lubrication and extreme pressure protection are the two most essential characteristics of the fluid.

Boundary Lubrication and Mixed Film Lubrication

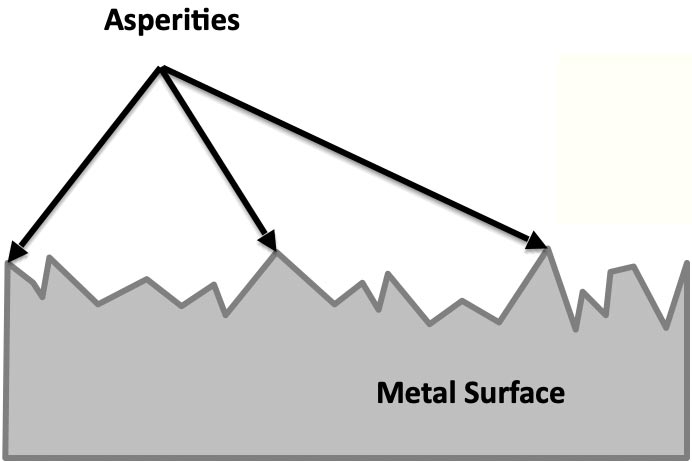

The two main focuses for metal cutting are boundary lubrication and mixed film lubrication. However, first it’s important to understand how specialty additives work to protect the metal surfaces of the tool and workpiece. Although the metal surface may appear to be smooth to the naked eye, it is not. The surface actually contains asperities. Asperities are high spots on the surface that come into contact during wear or friction as seen in the picture to the right.

Boundary Lubrication

As we know, during metal cutting the tool comes into direct contact with the metal workpiece. When two rough metal surfaces come into close contact with each other their asperities will also be in close constant contact.

The local temperature at the point of cut can reach up to ~1,000 oC, which can cause the two surfaces to “weld” together. However, when extreme pressure additives are “activated,” they react with the surface of each metal to create a low shear strength film that prevents welding.

Mixed Film Lubrication

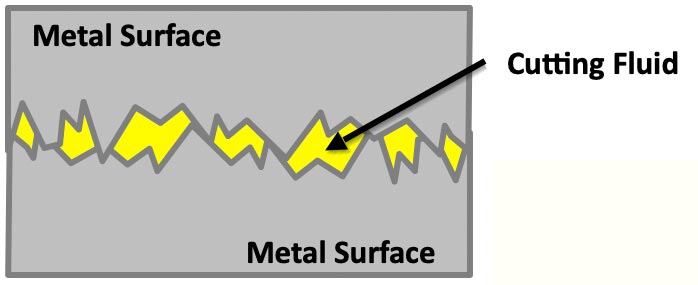

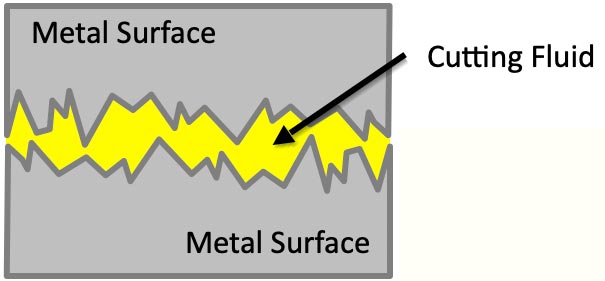

Mixed film lubrication is a combination of two different lubrication regimes: boundary and hydrodynamic. Hydrodynamic is when the lubricant provides a barrier, preventing the two surfaces from coming into close contact. Therefore, their asperities will not touch and there’s no need for extreme pressure additives. In mixed film lubrication, some asperities may still come into contact but not to the extent as boundary, as shown here.

While boundary lubrication happens at the point of cut, mixed film is found around the point of cut. That’s why cutting fluid lubricity additives are very important for protection, providing a cushion between the two surfaces by filling in around the asperities.

Conclusion

To enhance results of the machining process, specialty additives are added to improve cutting performance, corrosion protection, and extend oil and tool-life.

Primary additives include:

- Lubricity – include oil, natural fats and specialty esters that are attracted to the metal surface.

- Extreme Pressure – include chlorinate paraffins, sulfur and phosphorus compounds that react with the metal surface at different temperatures.

Secondary additives include:

- Anti-mist - which consist of long chain polymers that increase the size of the oil drops produced by rotating tools and workpieces.

- Copper corrosion inhibitors - prevent adverse surface reactions for yellow metals.

- Antioxidant - reduces the aging process of straight oils.