Protect Your Final Machined Products from Rusting

Unprotected Rusted Beam

At JTM Products Inc., we recognize that not every part that is machined will go immediately to the next process on its way to creating a final product. Newly machined parts are especially susceptible to corrosion and rust because of their fresh, unprotected surface. If these parts are to be stored or even shipped after machining, manufacturers rely on corrosion protection either via in-process inhibitors that leave an imperceptible thin film once the machining operation is complete, or via long term films applied after the machining process. JTM Products Inc. offers rust preventives that provide anywhere from a couple of days of indoor protection to 24 months of outdoor protection.

JTM has 3 options for preventing rust and avoiding parts that look like the beams in this photo.

Temporary In-Process Corrosion Inhibitor: designed for in-process or indoor rust prevention

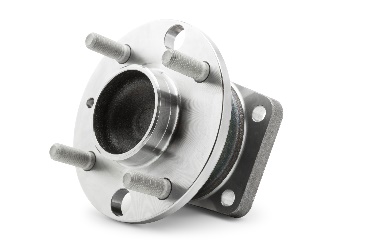

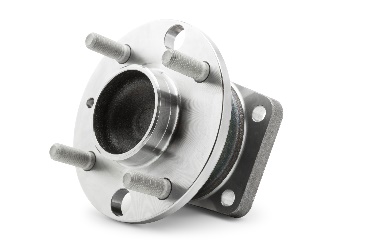

Protected Component

- Oil-free, full synthetic water-based corrosion inhibitor.

- Formulated to provide protection on steel surfaces during machining processes or in between subsequent operations.

- This thin-film product is dry to the touch and imperceptible on the metal surface.

Why use an in-process corrosion inhibitor? To protect the metal components of the machine, the tool, as well as the finished part. In-process corrosion inhibitors are water-based and therefore are low VOC and typically compatible with the metalworking coolant being used. Once water evaporates, the film left is invisible to the eye. Although traditionally applied via the coolant itself, water-based in-process preventives can also be applied via dip tank or spray.

Short and Long Term Rust Preventives: designed for indoor or outdoor protection during storage and/or shipping

Protected Steel Rolls

- Solvent and oil combination product.

- Formulated to provide short-term, indoor rust prevention of cleaned and washed parts for six months to a year dependent on the material and indoor storage environment.

- This thin-film product is dry to the touch and imperceptible on the metal surface.

Protect Rite 1208

- Solvent based product.

- Formulated to protect ferrous and non-ferrous materials from rust. Protect Rite 1208 is designed to provide up to 24 months of outdoor protection and unlimited indoor protection.

- This thicker film product is dry to the touch.

|

Protect Rite 401 |

Protect Rite 1206 |

Protect Rite 1208 |

| Storage and Shipping Coatings: Finished Parts or Raw Stock |

< 3 months covered |

3-24 months covered |

24+ months uncovered |

| Pickling Oils: Acidic Environment |

Not recommended |

Not recommended |

24+ months uncovered |

| Slushing Oils |

< 3 months covered |

3-24 months covered |

Not recommended |

| Dip Tank Fluids |

< 3 months covered |

3-24 months covered |

Not recommended |

| Automotive: Underbody and Innerbody Coatings |

Not recommended |

Not recommended |

24+ months |

| Structural Steel Maintenance Coatings: Bridges, Storage Tanks, Towers, Frames, Stored Equipment/Machinery, etc. |

Not recommended |

Not recommended |

24+ months |

| Wire Rope Coatings |

Not recommended |

Not recommended |

24+ months |

Our mission is to develop industrial lubricants and chemicals that represent new technology with obvious value to our distributors and their customers. Please contact your JTM Products Inc. representative to learn more about our available Corrosion Inhibitors.

ETNA Products

16824 Park Circle Drive, Chagrin Falls, Ohio 44023

Phone: 800-229-3862 / 440-543-9845 Fax: 440-543-1789

Copyright ©2025 ETNA Products, Inc. KOOLRite and SynMAX are trademarks of ETNA Products, Inc.

|

Protect Machined Products from Rusting

|

|

Protect Machined Products from Rusting

|

16824 Park Circle Dr, Chagrin Falls, Ohio 44023

Phone: 800-229-3862 / 440-543-9845

Fax: 440-543-1789

Copyright ©2025 ETNA Products, Inc. All Rights Reserved.

KOOLRite and SynMAX are trademarks of ETNA Products, Inc.